Technology Demonstration

On January 16, 2019, a first-of-its-kind demonstration of Deep Isolation’s patented technology was conducted using standard drilling techniques at a commercial drilling test facility. With over 40 observers from multiple countries, attendees included representatives from the U.S. Department of Energy, nuclear and oil & gas industry professionals, investors, environmentalists, and local citizens. This first-of-its-kind demonstration represents a significant milestone for the nuclear waste industry. A prototype disposal canister (containing no waste) was successfully placed and retrieved from a deep horizontal drillhole. This event also underscored the entrepreneurial potential of a private-public partnership approach for solving this global problem.

Lowering the Canister

The demonstration began with the lowering of the prototype canister ~2000 feet down the vertical section of a test drillhole that met our design specifications. The canister was then pushed into the drillhole’s horizontal section for over 400 feet using an underground “tractor.”

Participants were able to witness the insertion of the canister and the surfacing of the empty wireline after it was placed via live feed from the rig. The demonstration also included a tour of the test rig and site while the test was being conducted.

Drilling specialists at the demonstration explained and answered questions about how a canister designed to contain a fuel assembly would travel without bending through a drillhole that transitions from vertical to horizontal as well as how standard a process this is for the industry.

While the oil and gas industry has already perfected directional drilling, Deep Isolation is using it for an unexpected and extremely important new application. This approach was previously considered impossible by many nuclear waste experts in part because of the challenge of retrieval.

No radioactive material was used in the test, and the location was not one where actual waste would be disposed.

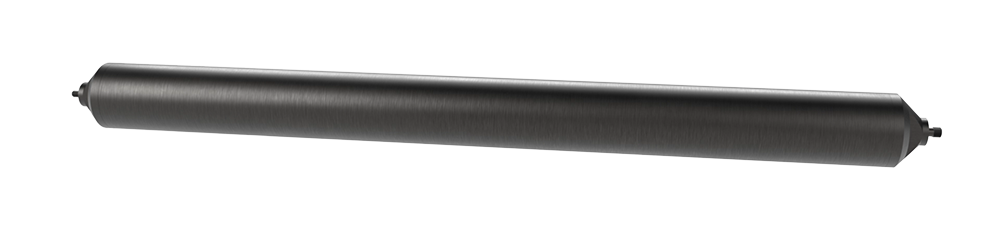

Test Canister Prototype

One of Deep Isolation’s prototype canisters designed to hold highly radioactive nuclear waste was also on display. Even though it held no waste, it did include a steel rod to simulate the weight of true waste. This canister was made specifically to fit within the test drillhole specifications. The prototypes are currently on display at the corporate office.

Surfacing of the Empty Wireline and Canister Retrieval

Once the canister was in place, it was released and the cable was withdrawn back to the surface to reveal the empty wireline to the observers at the demonstration.

Later, a tractor and relatching assembly were again lowered down the drillhole to re-attach the canister and bring it back to the surface.

Community Engagement Critical for Success

Deep Isolation’s core value of building consensus through genuine stakeholder engagement was also put to the test. Elizabeth Muller, Deep Isolation’s CEO emphasized that “Stakeholder engagement is where our solution began. Meaningful consultation cannot happen once a technology has been confirmed. To prepare for this public demonstration, we met with national environmental groups, as well as local leaders, to listen to concerns, incorporate suggestions, and build our solution around their needs and our customers’.”

Additional Resources

Disposal of High-Level Nuclear Waste in Deep Horizontal Drillholes

Dr. Richard Muller introduces our method and issues pertaining to safety requirements.

Thermal Evolution near Heat-Generating Nuclear Waste Canisters Disposed in Horizontal Drillholes

This paper examines the impact that design parameters and host-rock thermal properties have on temperatures in and around the drillhole.

Technology Demonstration Webinar

Watch our 1-hour webinar to learn more about Deep Isolation and our technology demonstration.