Deep Isolation Technology

What is the Deep Isolation concept, in simple terms?

Deep Isolation will emplace nuclear waste in corrosion-resistant canisters (typically 9 to 13 inches in diameter and 14 feet long) deep into horizontal drillholes, in rock that has been stable for tens to hundreds of millions of years.

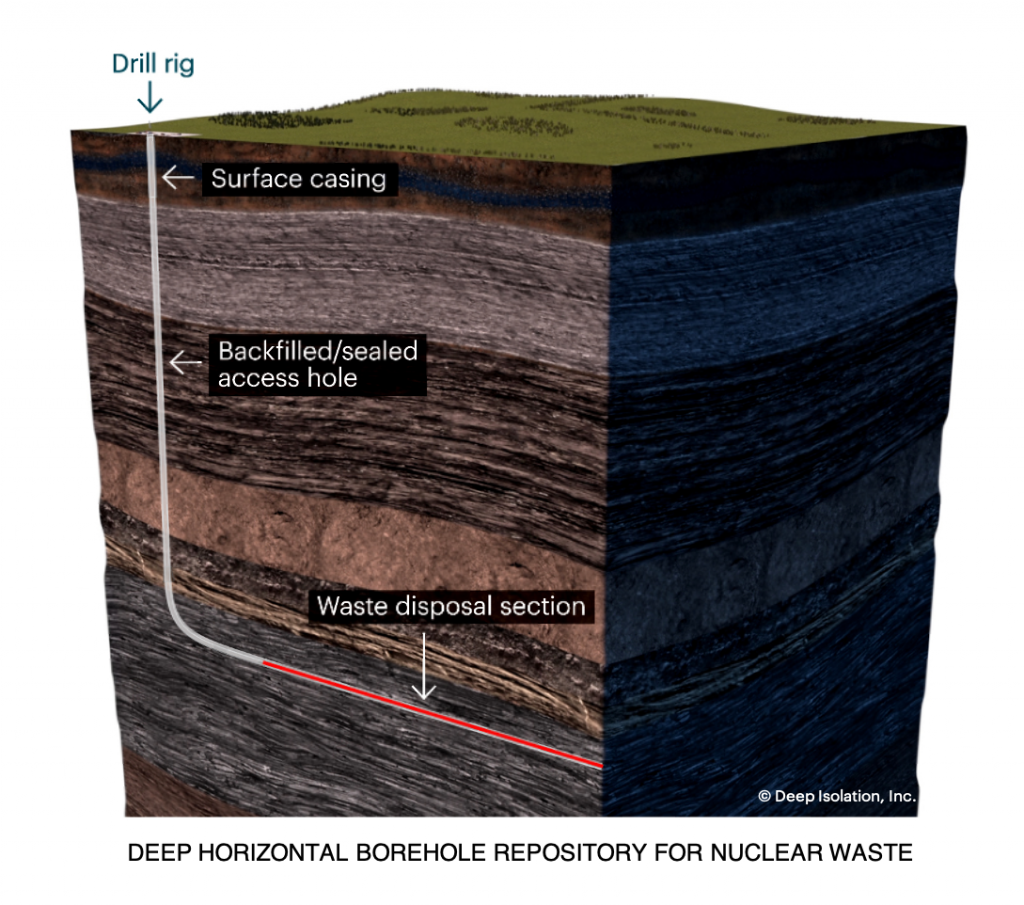

A Deep Isolation drillhole begins with a vertical “access” section that goes down from a few thousand feet to a few miles, depending on the geology. The drillhole then gradually curves, over a distance of typically 1000 feet, until the hole is near horizontal. (We give it a slight upward tilt for additional safety.) This (nearly) horizontal part we refer to as the “disposal” section.

Once the waste is in place, the vertical access section of the drillhole and the beginning of its horizontal disposal section are sealed using rock, bentonite and other materials.

Virtually all committees of scientists convened to study the disposition of nuclear waste have concluded that deep geologic burial (1000 feet or more) is the best disposal solution. Most previous approaches have assumed this requires large excavated tunnels for emplacement of the waste.

The key advantages of the Deep Isolation method are the depth of burial and the fact that the waste is stored in a suitable geologic formation far below the water table, in rock that is saturated with brine that has no commercial value and has been virtually stagnant for millions of years. In addition, the small diameter drillholes require less disturbance of the rock than a mined repository.

The horizontal drilling technology that will be used is highly developed and can be implemented at a relatively low cost. It can be modular, thus minimizing transportation concerns by allowing disposal at or near the generation site. Cost and safety are also improved by the fact that no person needs to go underground during construction.

Canisters containing nuclear waste would be stored in the deep horizontal section. One section (~1.5 km long) can store 6 years of waste from a Boiling Water Reactor (BWR) and 10 years of waste from a Pressurized Water Reactor (PWR).

For an illustration of a Deep Isolation drillhole, see Figure 1.

Would a Deep Isolation repository be located at each individual reactor site or would it be a central repository that would accept spent fuel from all reactors across the USA?

The Deep Isolation approach is modular, with minimally invasive boreholes that could be located around the country at or near waste generation sites or located at a regional or central repository location. The exact approach will depend on the needs and requirements of the host community and other key stakeholders.

Can you really put three miles of continuous steel liner (a “casing”) down the drillhole (1 mile of vertical access and 2 miles of horizontal storage)? How does it get around the curved section?

It is standard practice in the extractive industries to have wells lined with a continuous steel casing go down vertically for over a mile and horizontally for two miles. Some wells are several miles deep vertically and over five miles horizontally. The well casing is comprised of 30-foot-long sections screwed together at the drilling rig as they are lowered into the hole. The steel casing bends easily around the curve from vertical to horizontal after reaching the “kickoff point.” A typical distance to go from vertical to horizontal is 1000 feet. However, we cannot bend our disposal canisters containing the spent nuclear fuel assemblies. So, depending on the length of our canister and the diameter of the drillhole, the curve to transition from vertical to horizontal may take 2000 feet instead of 1000 feet.

Do you pick sites that are suitable for natural resource recovery?

The ideal geology for waste isolation has no recoverable natural resources. We prefer to drill in or under shale rock that is high in clay content, making it more ductile, self-healing (so fractures don’t endure), and thus unsuitable for resource extraction.

Why didn’t someone think of this before?

The Yucca Mountain tunnel repository was designated as the sole repository option by the U.S. government in 1987 and was supposed to begin accepting our nation’s waste inventories in 1998. When Yucca Mountain stalled, no alternatives could be considered because the Nuclear Waste Policy Act (NWPA) specified that Yucca Mountain was by law the only option. Our solution would provide an additional disposition pathway for commercial spent nuclear fuel if the NWPA can be amended to allow DOE to apply for a license using the Deep Isolation method.

Didn’t the Department of Energy try this and why didn’t it work?

The Department of Energy tried to start a test program for vertical boreholes intended for defense waste (such as the waste stored at the Hanford facility in Washington State or the Savannah River facility in South Carolina). This program envisioned vertical boreholes even deeper than ours, drilled into crystalline basement rock such as granite. The founders of Deep Isolation were familiar with this program but felt that there was a great advantage to drilling into less brittle rock and taking advantage of directional drilling.

Why is the horizontal section of the Deep Isolation concept necessary?

The horizontal section (the disposal section) of the drillhole allows waste to be placed end-to-end (with some spacing between the waste canisters). This end-to-end placement results in a lower thermal heat load than a mined repository or vertical borehole and placing the canisters horizontally provides more support for the waste canisters. The horizontal aspect also allows for less disturbed rock directly over the waste. An 18” drillhole will have approximately 9” of disturbed rock around the drillhole, but the remainder of the thousands of feet of rock between the waste and the surface will remain undisturbed.

For the generic disposal design, how many fuel assemblies per canister, and how many canisters fit into the waste disposal section of one borehole?

Each canister contains a single spent fuel assembly from a Pressurized Water Reactor (PWR). A 1 km-long disposal section holds about 150 canisters. An array of 10 parallel disposal sections holding a total of 1,500 PWR assemblies would accommodate the waste being produced by a 1,000 MWe nuclear power plant in 30 years.

What keeps the radioactivity from reaching the surface?

The disposal section of the drillhole is buried thousands of feet underground, under a billion tons of rock, including layers that have held volatiles (methane) for millions of years. The potential release path is for the radioactive material (e.g. radioactive iodine found in the pellets) to dissolve in deep water which could then be transported to the surface.

We plan to prevent this by a combination of engineered barriers (low-corrosion metal for the canisters) and the geologic barrier which is the rock. Engineered barriers include the ceramic pellets themselves, the metal rods that contain them, the sealed corrosion-resistant canisters that hold the rod assemblies, the steel casing that lines the drillhole, and the sealed drillhole. These engineered barriers are expected to provide protection for tens of thousands of years.

For the geologic barrier, a formation will be considered suitable if we can demonstrate beforehand that the water at depth is extremely stagnant and has been out of contact with the surface for hundreds of thousands to millions of years.

Why a mile deep?

One mile is typical; in some locations, the best depth might be a few thousand feet; at others, it might be two miles or more. The waste is placed far below aquifers, in regions in which water has had no contact with the surface for thousands to millions of years or more. What we are seeking are the geologic environments best suited to dispose of the waste for the years to come.

What is a suitable geologic environment to safely isolate nuclear waste in the Deep Isolation solution?

Nuclear waste disposal is a global challenge and we are developing a solution that can be adapted to work in a number of different geologic settings.

Directional drilling technology allows Deep Isolation to precisely place nuclear waste 1-3 kilometers beneath the surface in carefully selected geologic formations. The target geologic media for our repositories are in or below formations that have been out of contact with surface waters for millions of years. This is a robust predictor of future isolation that can be determined by a number of isotopic age dating methods.

In addition to having demonstrated past isolation, it is important to consider fundamental rock properties and the regional seismic and hydrologic setting. In general, we seek rock types that have low permeability and hydraulic conductivity, a capacity for self-healing fractures, and which have the ability to adsorb radionuclides and inhibit their mobility. The primary formations which demonstrate these traits are deep sedimentary strata, such as clays, mudstones, and shales as well as salt formations.

In regions that lack these lithologies, other non-sedimentary rock types such as granite or crystalline basement are promising options for repositories if they demonstrate long term isolation capacity. In many regions of the world very old crystalline basement rocks have waters at depths between 1-3 kilometers that have remained isolated for tens to hundreds of millions of years. This is determined by measuring the accumulation of noble gases such as helium, argon, or neon which are produced within the rock deep underground.

We believe that there can be many good options for disposal, and a reasonably thorough search in most countries will reveal several satisfactory options. These options can be explored and evaluated through detailed geologic, hydrologic, and seismic studies, as well as through isotopic testing and repository modeling to help clarify which sites and formations are most suitable.

How do you put the fuel down there?

We take the spent fuel assemblies from their current storage location – a cooling pool and/or dry cask storage pad – and place them into canisters which are then filled with a sand-like material and welded shut. The canisters are lowered into the vertical access section of the drillhole and then pushed into the horizontal disposal section using drill pipe, coiled tubing, or wireline with tractors. For retrieval, the process is reversed.

To place the spent nuclear fuel into the disposal canister we will need to transfer it from pools or from dry casks. The transfer of fuel assemblies from pools to dry casks takes place at the reactor using cranes and other equipment. There is considerable experience with the movement and transfer of spent nuclear fuel assemblies. The methods and operations for moving from pool to dry cask can be adapted to moving assemblies from dry cask to our disposal canisters. We could also use mobile hot cells instead of pools for facilities that have been decommissioned and no longer have a cooling pool on site.

Does the fuel assembly have to be repackaged to fit in the canisters?

Each fuel assembly will need to be removed from the dry cask and the fuel assembly will need to be repackaged prior to emplacement in a Deep Isolation drillhole. The existing fuel assemblies are typically 8 to 12 inches in diameter and 14 feet long. The Deep Isolation disposal canisters have been designed to accept the fuel assemblies “as is.” The filled canisters are then lowered into the drillhole.

How can a vertical drillhole bend to allow horizontal storage?

Directional drilling of curved drillholes is a highly developed art. The curvature is gradual; the initial hole is vertical, and at the “kickoff” depth a gradual curvature begins; the transition to horizontal has a radius of curvature that is between 200 and 1000 feet long. There are no abrupt turns. The long steel casing pipe that is inserted to line the drillhole can make the turn.

See Figure 1.

Has this drilling technology been tested?

The drilling technology has been used for over 50,000 boreholes drilled by the resource extraction industry in the US during the past two decades. This is a well-developed technology and has become a low-cost commodity.

The Deep Isolation solution was also successfully tested at a commercial drilling facility where a prototype canister was successfully lowered 2200 ft. (670 meters) into an existing drillhole using a wireline cable and then pushed over 400 ft. (122 meters) using an underground “tractor” into a long horizontal storage section. The canister was released and the tractor and cable withdrawn. Several hours later, the tractor was placed back in the hole, where it latched and retrieved the canister, bringing it back to the surface.

Can the waste be retrieved?

Yes. The Nuclear Regulatory Commission (NRC) requires waste to be retrievable for a period of time. The drilling industry regularly retrieves objects and monitoring instruments from drillholes, and the process is standard. Before a Deep Isolation drillhole is sealed, an expert crew could still retrieve the waste, but it would take a week or possibly longer. Doing so is sufficiently complex to offer substantial security from a terrorist attempt to retrieve the waste. We have already demonstrated the canisters can be retrieved.

What if a canister gets stuck in a hole?

If there are unexpected challenges with retrieving an object, then there are specialist companies that can “fish” for uncooperative objects such as a broken pipe. They regard retrieval of a canister, something that is “cooperative” (has structures purposefully built-in to make connection easier), as straightforward. We are in the process of conducting our own tests to ensure retrieval of our canisters could be accomplished in the same manner.

If for some reason, retrieval and fishing fail, then no further waste will be placed in the hole and the hole can be monitored, and eventually sealed.

How will you monitor the waste in the drillhole?

During emplacement and while the drillhole is open, in-place monitors would record heat and radioactivity at depth. After sealing and closing the drillhole, air and water sampling nearer the surface would also take place. There is a performance monitoring period for our drillholes that will be determined as part of the licensing process.

Would the drilling cause earthquakes?

No. Drilling and emplacement do not cause earthquakes. We do not use explosives or high-pressure water subsurface. The earthquakes observed from certain extractive industry drilling come from high-pressure reinjection of produced water, and we will not be doing anything like that. Compare the risks of fracking with the safety of the Deep Isolation solution.

Will you be utilizing long-haul transportation of waste as part of your solution?

The Deep Isolation approach is modular, with minimally invasive drillholes that could be located around the country at or near nuclear reactor sites. If a community and state provide informed consent, the drillholes could be put close to the nuclear reactor that created the waste.

If putting the Deep Isolation drillholes near the reactor is not possible, then another location could be found within a shorter or longer distance, depending on what the people of the state want.

What kind of steel will be used and how thick?

The casing that lines the drillhole is typically made of carbon steel, but other materials could be used. The space between the casing and the drillhole could be filled with cement. The canister can be made of a corrosion-resistant alloy that is expected to endure underground for thousands of years. The very long-term isolation (over tens of thousands of years to even a million or more) is provided by the deep, highly impermeable and stable geologic formations.

Won’t the canisters and casings quickly rust?

With Deep Isolation’s solution, the spent fuel canisters will be in contact with a “reducing environment.” Basically, this means very low oxygen in either gas or chemical form. Oxygen is a key element for many kinds of rust, and the low oxygen means that the corrosion-resistant alloys will last for a very long time. They will in time erode and that is why the geologic barrier is so robust and remains the primary barrier.

How soon can you dispose of existing waste?

The technology is available now, and the time to implement a solution is a few months to mobilize and drill the disposal drillhole once the license is obtained from the Nuclear Regulatory Commission (NRC) in the U.S. Internationally, with the right customer and government support, Deep Isolation could begin safely disposing of commercial waste within 2-3 years.

Would you be a competitor to Yucca Mountain?

Rather than viewing ourselves as competitors, we view Deep Isolation’s solution as a supplementary approach for those sites and states that have suitable geology and a community that prefers local or in-state disposal.

Is your solution ready for market and which markets do you intend to sell to?

Yes. Our solution is ready and our focus is in the United States, as well as countries in Europe and Asia. Nations with smaller inventories of waste may find that horizontal drillhole disposal is especially cost-effective.

Community and Public Support

Wouldn’t communities reject disposal in their backyards?

About 1/3 of U.S. citizens already live within 50 miles of a place where nuclear waste is stored above ground in cooling pools or dry casks. Deep Isolation would take that waste and put it thousands of feet underground, protected by over a billion tons of rock. This would make the waste safer and more secure than the status quo.

Deep Isolation has talked with people in many affected communities and in 2018 engaged the highly respected firm GfK Global to survey the opinions of people living in over 20 states. On average 82% of those surveyed prefer deep burial on-site rather than transportation over local roads to distant storage facilities. They do not want waste brought in to their communities from outside, nor do they want waste transported across their state. Read the results.

Deep Isolation will only work with communities and states that give their support for the permanent isolation of nuclear waste in their community and state. If a community and state are not interested in our permanent disposal method, they can still advocate for the waste to be shipped to an interim site, or a different disposal facility when one becomes available.

The decision process as to whether a community and state would prefer to transport waste to another location or dispose of it nearby is a complex one. Potential benefits of permanent isolation in their community and state include a timely solution that improves safety, minimizes transportation, adds jobs, and provides new fees for the use of land. Only if the community and state decide the benefits make it worthwhile would a site be selected there.

Deep Isolation will work with communities and states to help them make an informed decision about which option is the best fit for them. With over 60 locations in the United States that are currently storing nuclear waste in pools or dry casks, we have indications that at least a few of them are interested in exploring the option of a Deep Isolation facility.

What kind of consent is required from the local community?

“Informed consent” is a minimum requirement for Deep Isolation. We seek to partner with communities and states that have a strong understanding of the safety and other benefits that could be realized from safely isolating the waste instead of waiting to see when and if a centralized storage or disposal option will be realized.

Deep Isolation will make communities and states full partners in the approach to safely isolating waste. Each partnership will be tailored to their specific needs and interests. This partnership would impact both the design of the Deep Isolation facility, the way that the project is implemented, and the specific benefits available. Our commitment to communities is that they will be better off having partnered with us. We are not proposing a “one size fits all” solution.

What will happen if the community is not interested?

We will work only with communities and states who decide that Deep Isolation is preferable to the other available options.

Why would a community consider a Deep Isolation disposal solution?

Those that choose a Deep Isolation solution will do so because they prefer the certainty of having the waste disposed of deep underground (as it is intended to be), as opposed to the uncertainty of it remaining in pool or cask storage above ground near their community. Although the waste would not be transported to a distant location, our on-site disposal will meet and in some cases exceed federal and state requirements. We believe that from a variety of aspects a Deep Isolation solution will leave a community better off than they were before.

Does the public think that the U.S. government is the only appropriate organization to solve the waste problem?

No, quite the contrary. A recently published three-year study from Stanford University recommends that the United States reset its nuclear waste program by moving responsibility for commercially-generated, used nuclear fuel away from the federal government and into the hands of an independent, nonprofit, utility-owned and -funded nuclear waste management organization.

Additionally, a (2018) survey done by the highly respected firm GfK Global, was designed to reach a representative cross-section of the American public. Their poll found that 70% of Americans think the private sector should be able to propose solutions, and over 90% believe that allowing innovation in nuclear waste disposal would be a good thing to do. View the results of the GfK survey.

Would there be jobs for the local communities?

Drilling and construction would be done by a local firm whenever possible. Monitoring and inspections are expected to last up to 50 years after the emplacement of the waste, and this could be done by specially-trained and qualified local workers. The specifics of these jobs would be discussed and agreed-upon as part of the partnership agreement.

Safety

How much radioactivity will be emitted by the spent fuel before the repository is sealed? How much after the drillhole is sealed?

Nuclear radiation is emitted by the canisters whether above or below ground. Virtually all of this consists of “gamma rays,” which are like high-energy X-rays. To assure safety, there will be shielding between the canisters and any workers. Once underground, the rock will provide shielding and safety for the environment and human health.

At all times, the drillhole will be in compliance with regulations for the release of radioactive isotopes and radioactive dose to the public. The release of radioactive isotopes has been specified by law and regulation. These laws and regulations are written in highly technical language, but generally speaking, they assure that no human-harmful levels of radioactivity will reach the surface for tens of thousands to millions of years. The geologic formations chosen for the Deep Isolation drillholes will have been stable for tens to hundreds of millions of years. Ultimately, it is the geology that provides long-term confinement.

How will workers and the environment be protected during insertion?

Methods for moving the waste have been highly developed by the nuclear industry to protect workers and the environment. They have already been used for the transfer of waste from the nuclear reactor to the cooling pools, and for the transport of waste from the pools to dry casks at the reactor site. Deep Isolation will ensure that the top priority will be to fully protect the worker and the environment when emplacing waste in drillholes.

Will you be removing waste from dry casks and if so what are the process and safety issues?

Yes, we would be removing spent nuclear fuel from dry casks. The transfer of fuel assemblies from pools to dry casks takes place at the reactor using cranes and other equipment. There is considerable experience with the movement and transfer of spent nuclear fuel assemblies. The methods and operations for moving from pool to dry cask can be adapted to moving assemblies from dry cask to our disposal canisters. We could also use mobile hot cells instead of pools for facilities that have been decommissioned and no longer have a cooling pool on site.

During insertion into the drillhole, the transfer cask will be placed above the drillhole and the canisters lowered into the drillhole. The main safety concerns are for the people working at the site. For this reason, the operations will be conducted remotely using well-developed procedures for monitoring and safety.

The safety issues during the process are related to exposure to the workers and the potential handling accident from the movement of the assemblies. The workers will be well-trained, and the work will be done following detailed procedures. The risks associated with the movement of the assemblies will be continuously reviewed to ensure safety.

Will the encased spent fuel be as safe as dry casks?

Yes. The U.S. National Academy of Sciences concluded that the ultimate disposal of spent nuclear fuel should be done deep underground in stable geologic formations. Dry casks offer an “engineered barrier.” We consider dry cask storage to be safe for interim timeframes, but nobody claims it is safe for longer term disposal (hundreds to thousands of years and longer). For long-term disposal, many people have argued that a combination of an engineered barrier and a geologic barrier offers redundancy against the unexpected. Deep Isolation offers this redundant combination.

Is it safeguarded from terrorists?

Deep geology provides a barrier that gives significant protection against a terrorist attempt to obtain spent nuclear fuel. Although the spent fuel is retrievable, doing so requires setting up a rig, removing thousands of feet of rock and bentonite sealant, and operating a fishing system to pull up canisters one at a time. That is a process an experienced crew can accomplish but the cost and difficulty does not lend itself to a surreptitious terrorist attack.

Can Deep Isolation meet the NRC standard that a member of the public be exposed to no more than 15 mrem per year?

Yes. We believe we can achieve the 15 mrem standard set by the Environmental Protection Agency and adopted by the NRC, but we are adopting an even stricter standard of 10 mrem per year as a means to provide an extra margin of safety.

Figures

Figure 1 (below). The Deep Isolation drillhole waste repository concept. The horizontal section of the drillhole will be 18 inches wide, which will fit the 9 to 13 inch diameter of the disposal canister.

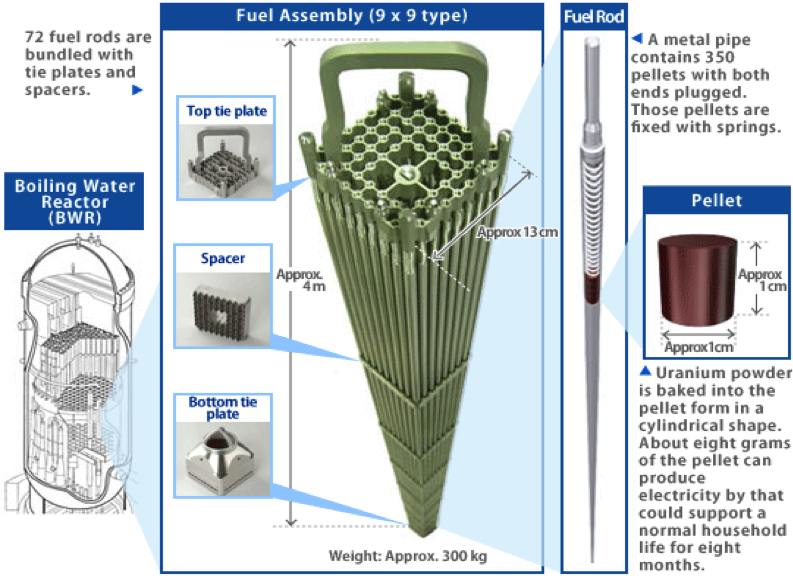

Figure 2 (below). A typical nuclear fuel assembly. The one shown below is a common design for a Boiling Water Reactor (BWR). The fuel pellets for Pressurized Water Reactors are the same size but are placed in somewhat larger fuel assemblies that contain more rods. The fuel assembly would be placed in canisters that fit conveniently down drillholes.